The importance of quality control in manufacturing has increased due to the daily expansion of production units. No manufacturer wants to put customers through the trouble of having to buy a subpar product, but it is not possible to manually monitor every product that leaves the facility.

Therefore, quality control plays a constant role in a manufacturing facility. You will learn about the advantages of quality control in the manufacturing process, as well as instances of quality control in action, in this article.

Quality Control (QC): What Is It?

A company uses quality control (QC) as a process to make sure that the quality of its products is either maintained or increased. The organisation must foster a culture of perfection among management and staff in order to implement quality control. This is accomplished through staff training, setting standards for product quality, and testing goods to look for statistically significant differences.

The creation of precise controls is a crucial component of quality control. These measures aid in standardising output as well as responses to problems with quality. Reducing margin for error by clearly defining which production tasks are assigned to which personnel lowers the possibility that workers will perform tasks for which they are ill-prepared.

Quality Assurance vs. Quality Control

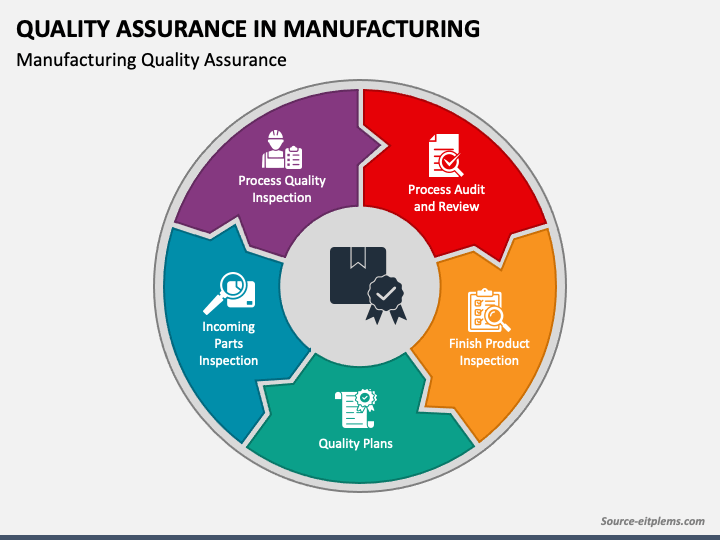

Although quality assurance and control are sometimes used synonymously, they are not the same. Meeting quality requirements is the main goal of the wider quality management process, which includes quality control.

The activities in the quality management plan that guarantee the production of your product are the focus of quality assurance, which is also a part of it. It indicates that you have confirmed that the planned quality requirements will be met during production.

Inspection is the time for quality control. As mentioned, the product is tested to ensure that it is both safe and effective. As a result, there are differences between how quality assurance and control collaborate to guarantee the calibre of the goods you manufacture.

The two differ from one another. First, quality control is reactive, whereas quality assurance is proactive. That is a result of the things they do and when they do them. While quality control concentrates on the product itself and searches for any problems with its quality that will affect the customer, quality assurance is process-oriented and preventative.

Benefits of Using Quality Control in Manufacturing

The following are some advantages of quality control in a manufacturing process:

High-quality responsivenessThe reason quality control is important in manufacturing is that it helps factory workers become more conscious of quality, which goes a long way towards helping the industry reach its goal of high-quality products. As a result, the manufacturing process is made to respond to and comply with the established quality standards.

Customer Contentment

Customer satisfaction is a given when you produce a product free of errors or defects. Quality control makes it easy for you to accomplish.

Decreased Wastage

Quality control guarantees that there is little material waste and maintains the product’s production quality. You can then cut production costs as a result of this.

Optimal Use of Resources

It not only lowers salaries and production costs, but it also aids in making the best possible use of all available resources. After the quality control procedure is completed, no raw material or other production component is misused or ignored.

Quality control techniques and method in manufacturing you can use

As was previously mentioned, a significant portion of quality control involves inspecting the finished goods and determining whether they comply with quality standards. You can use a variety of methods to guarantee the quality of your products, depending on the kind of products you produce, the laws, and global standards.

These are some different quality control techniques you can use in your manufacturing processes.

1. The 100% inspection approach

Using this method, you must inspect each and every one of your products to make sure they meet the quality standards.

For example, you might be legally obligated to ensure that all of your products, including food and medication, have expiration dates printed on their labels before they are shipped from your facility.

Nevertheless, this approach is frequently superfluous and can be highly costly. It is only used when producing a subpar product would come at a very high cost.

2. Techniques for statistical quality control

used as a catch-all phrase for various techniques that use statistics to carry out quality control. The foundation of all manufacturing quality control procedures is formed by these techniques. To implement quality control, they use particular techniques like quality control charts and acceptance sampling.

Acceptance sampling, for instance, involves selecting a predetermined number of products from the entire lot and inspecting them for flaws. If the quantity of defective products is less than a predetermined threshold, the lot is accepted as a whole; if not, it is rejected.

3.Examination

The most well-known and established QC technique, inspection is still applied in a variety of industries. The final product must be inspected to guarantee quality. The final inspection is what counts, even though there may be some upstream inspection or sampling done along the way. An important component of inspection-driven quality control is good manufacturing documentation and practices.

4.Management of Total Quality (TQM)

TQM is a tried-and-true quality improvement approach that is based on philosophy. It aims to instill quality in the company’s culture, teach all employees to recognise issues, and give them the authority to take appropriate action when needed. Modern software-driven TQM programmes are much more effective at regulating and guaranteeing quality when they are connected to a platform for data management such as MachineMetrics.

5.Careers in Quality Control

If you enjoy working with people, communicating, presenting findings, and improving and safety-enhancing products, quality control can be a fulfilling career. Depending on the industry, you’ll need in order to work as a quality control inspector.

A high school degree is required for entry-level jobs.

Bachelor’s degree, based on the field

Industry experience

certifications and licences required by specific businesses and industries

Additional attributes that professionals in quality control must possess are

Paying close attention to details

Math and mechanical abilities

Strength and physical prowess

Technical proficiency

Under pressure performance

6. Using lean manufacturing

Lean Six Sigma is a hybrid quality control approach that emerged as a result of the widespread adoption of lean manufacturing techniques. The book Leaning into Six Sigma: The Path to Integration of Lean Enterprise and Six Sigma first introduced it in 2001.

As the name suggests, it combines the highest standards of Six Sigma product delivery with the best lean inventory techniques, such as eliminating the eight different types of wastes (also known as Muda in lean).

How Can Quality Control Be Improved in Manufacturing?

You can enhance the goods you produce with the aid of the quality control procedure. But quality control techniques themselves also require modernization. Consequently, putting in place a strong quality control system guarantees that your products either meet or surpass consumer expectations.

The following are some strategies for enhancing manufacturing quality control:

Establish unambiguous quality standards.

Clearly state your quality standards to all staff members. By doing this, you can make sure that everyone is aware of the expectations and can cooperate to meet them.

Employees should get on-the-job training

Make certain that every employee has received sufficient instruction on quality control methods and protocols. Continuous training and reinforcement are necessary to guarantee that quality standards are continuously fulfilled.

Use advanced quality control tools

These tools such as statistical process control, process mapping, and quality control charts, to monitor and improve quality control processes.

Conduct regular inspections

Conduct regular audits to identify improvement areas and ensure quality standards are being met. Thus timely product and process inspections can help you detect and lessen errors in the next production cycle.

Involve employees in quality control

Involve them in quality control processes by encouraging them to identify improvement areas and participate in problem-solving activities. This will help create a culture of continuous improvement.

Evaluate, put into action, and enhance

Include analysis and remedial actions in your programme for quality management. This will give you a better understanding of your prior quality control procedure. Therefore, you can enhance your quality control procedures and guarantee that they continue to be successful and efficient over time by regularly reviewing and evaluating them.

Using Platforms for Machine Data

The amount of data needed for improvement is too big for human analysis, regardless of the QC method used or the industry. Manufacturers are empowered by real-time production data from MachineMetrics and other machine data platforms, which can be utilised to gain actionable insights from advanced analytics.

Operators and managers can instantly access data in formats that help them comprehend current performance and act quickly using the MachineMetrics platform. Additionally, the platform can be expanded to include the entire organisation due to its integration with other software programmes like MES, ERP, and QMS.

Box With Title Background

Create trendy looking dark boxes with a title background.