Supply Chain Management (SCM): What Is It?

Supply chain management (SCM) is the process of controlling the movement of products and services into and out of an organisation, including all steps necessary to transform raw materials and component parts into finished commodities and deliver them to the final consumer. A company’s operations can be streamlined with the aid of effective SCM to reduce waste, increase customer value, and gain a competitive edge in the market.

KEY LESSONS

Supply chain management (SCM), which encompasses all of the procedures involved in converting raw materials and component parts into finished items, is the central management of the movement of goods and services to and from an organisation.

.Companies may reduce unnecessary expenditures and deliver goods to customers more quickly and effectively by optimising the supply chain.

.Effective supply chain management can assist avoid costly product recalls, lawsuits, and negative press.

- .Planning, sourcing, manufacturing, distribution, and returns are the five SCM phases that are most important.

.Controlling and lowering expenses while preventing supply shortages are the duties of a supply chain manager.

Supply chain management benefits

Numerous advantages of supply chain management result in higher earnings, a better perception of the brand, and a stronger competitive edge. They consist of the following:

1.Better supply chain visibility, risk management, and predictive capabilities,

2.fewer process inefficiencies and less product waste, improvements in quality,

3.increased sustainability, from a societal and environmental standpoint,

lower overhead,

4.better cash flow, and more effective logistics are all benefits.

The Operation of Supply Chain Management

Supply chain management refers to a continuing endeavour by businesses to optimise the effectiveness and cost-effectiveness of their supply chains.

SCM often aims to centrally coordinate or link a product’s manufacturing, shipment, and distribution. Companies may save unnecessary expenses and stages by optimising the supply chain, and they can also deliver goods to customers more quickly. Internal inventories, internal production, internal distribution, internal sales, and the inventories of firm vendors are all closely monitored to achieve this.

SCM is predicated on the notion that almost every product that enters the market does so as a consequence of the efforts of numerous businesses that comprise a supply chain.

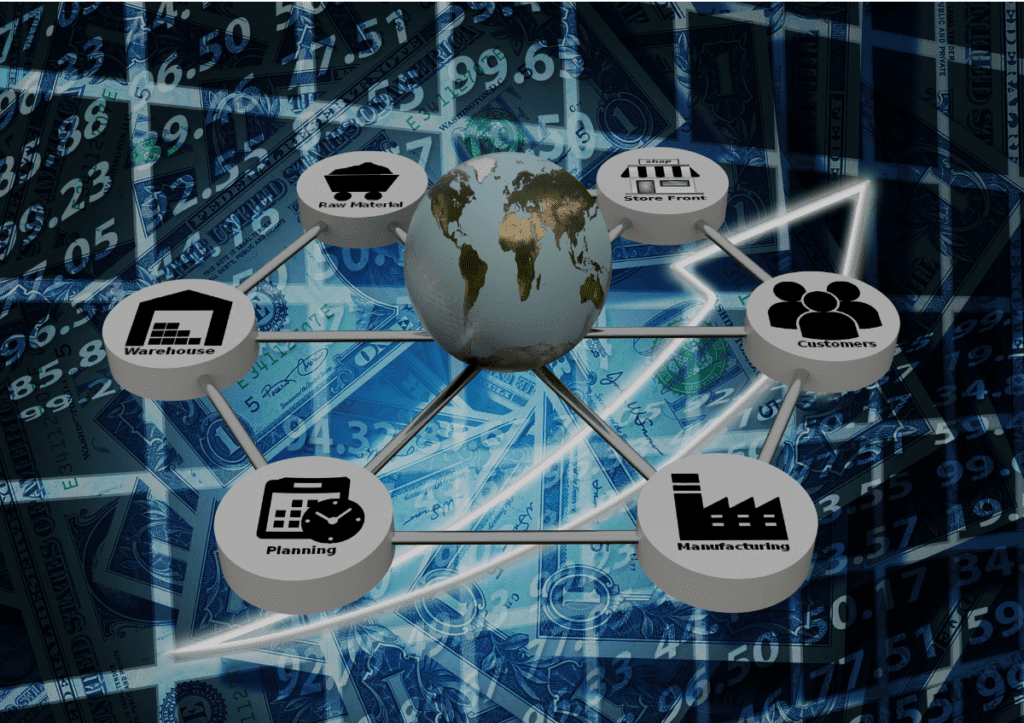

Managing the supply chain through five stages

Generally speaking, supply chain management can be divided into five steps or areas:

Plan. In order to meet customer demand for products and prevent a bullwhip effect, organisations develop strategic plans using supply chain analytics and materials management capabilities in ERP systems.

Source. In accordance with agreements, organisations identify and choose suppliers who can provide materials in a streamlined and effective manner. Collaboration in the supply chain begins at this point and is crucial throughout the supply chain management process.

Make. Products are manufactured in this stage. Production scheduling, testing, ensuring compliance standards are met, packing, storage, and release are all included. Involvement of multiple machines is probable, especially for larger companies,

Deliver. The logistics-related delivery stage is concerned with getting finished items to customers using whatever means of transportation are required. More attention is being paid to doorstep delivery as a result of the Amazon effect, particularly as a result of COVID-19. The importance of supply chain executives collaborating more closely with customer service has increased as well. Systems for inventory management and warehouse management are particularly important at this point.

Return. All product returns, including those for damaged or unsupported goods, are included in the return stage. Additionally, this level incorporates components from earlier stages, such as inventory and transportation management.

lowering supply chain dangers

The development of a successful supply chain is largely driven by effective risk management. Reduced quality and erratic shipping times are problems that come with supply chain cost cutting. Lean manufacturing, outsourcing, and offshoring are all common practises that raise risk levels. Utilising more contemporary strategies like supply chain redundancies, information tracking, flexible supply contracts, and risk assessment techniques, industries should seek the ideal balance between risk and cost.

Lynch advised against economising on shipping by taking short cuts. Small firms are better off finding a partner who can relieve them of the burden of transportation rather than increasing overhead, he asserted.

“Looking for transactional savings on shipments can hurt businesses in the long run,” Lynch furthered. While immediate savings of $20 to $100 will be noticeable, there are considerable long-term expenses and implications.

Lynch advises you to carefully consider your transport provider.

He makes the point that the person who provides transport is frequently the last to interact with your consumer and thus leaves the last impression of your business.

Supply Chain Model Types

The way supply chain management is implemented varies depending on the company. Each company’s SCM process will take into account its own objectives, limitations, and advantages. These are just a few of the models that a business might use to direct its supply chain management initiatives.

Model of continuous flow: One of the more established supply chain strategies, this model frequently works best for established sectors. The continuous flow model assumes that a company will consistently produce the same good and that customer demand will be stable.

Agile business models: These models work best for firms that produce goods on a bespoke basis or with erratic demand. This model places an emphasis on adaptability because a business may need to meet a specific requirement at any time pivot accordingly

Fast model: This model places an emphasis on a product’s rapid turnover due to its brief life cycle. A corporation uses the rapid chain model to try to take advantage of a trend, produce products quickly, and make sure the product is completely sold before the trend ends.

Flexible model: Businesses impacted by seasonality do better using the flexible approach. During the busiest times of the year, certain businesses may have very high demand requirements and very low volume requirements. An adaptable supply chain management approach makes sure that production can be rapidly ramped up or shut down.

Efficiency model: Businesses that compete in sectors with extremely slim profit margins may try to gain an edge by optimising their supply chain management procedures. This also applies to using equipment.

How Important Is Supply Chain Management?

Supply chain management is crucial since it can aid in achieving a number of corporate goals. Controlling production procedures, for example, can enhance product quality while lowering the likelihood of recalls and legal action and assisting in the development of a powerful consumer brand. Controlling shipping processes can also enhance customer service by preventing expensive shortages or periods of inventory overstock. Overall, supply chain management offers numerous chances for organisations to increase their profit margins and is particularly crucial for those with significant global operations.

Supply chain management software’s function

Today’s supply chains must be managed using technology, and ERP suppliers provide modules that concentrate on important SCM tasks. There are additional vendors of business software who specialise in SCM. Several significant points to be aware of are as follows:

.Inventory management software for tasks like monitoring and optimising stock levels;

supply chain planning software for tasks like demand management;

.supply chain execution software for tasks like daily manufacturing operations;

.supply chain visibility software for tasks like spotting and anticipating risks and proactively managing them;

.logistics management software and transportation management systems for tasks like managing the transportation network

The rise of e-commerce, with its emphasis on almost instantaneous small delivery straight to consumers, and the increasingly global nature of today’s supply chains are providing issues, notably in the areas of logistics and demand planning. Numerous tactics, like lean manufacturing, and more recent methods, like demand-driven material requirements planning, could be useful.